The Development and Functionality of Electric Motors

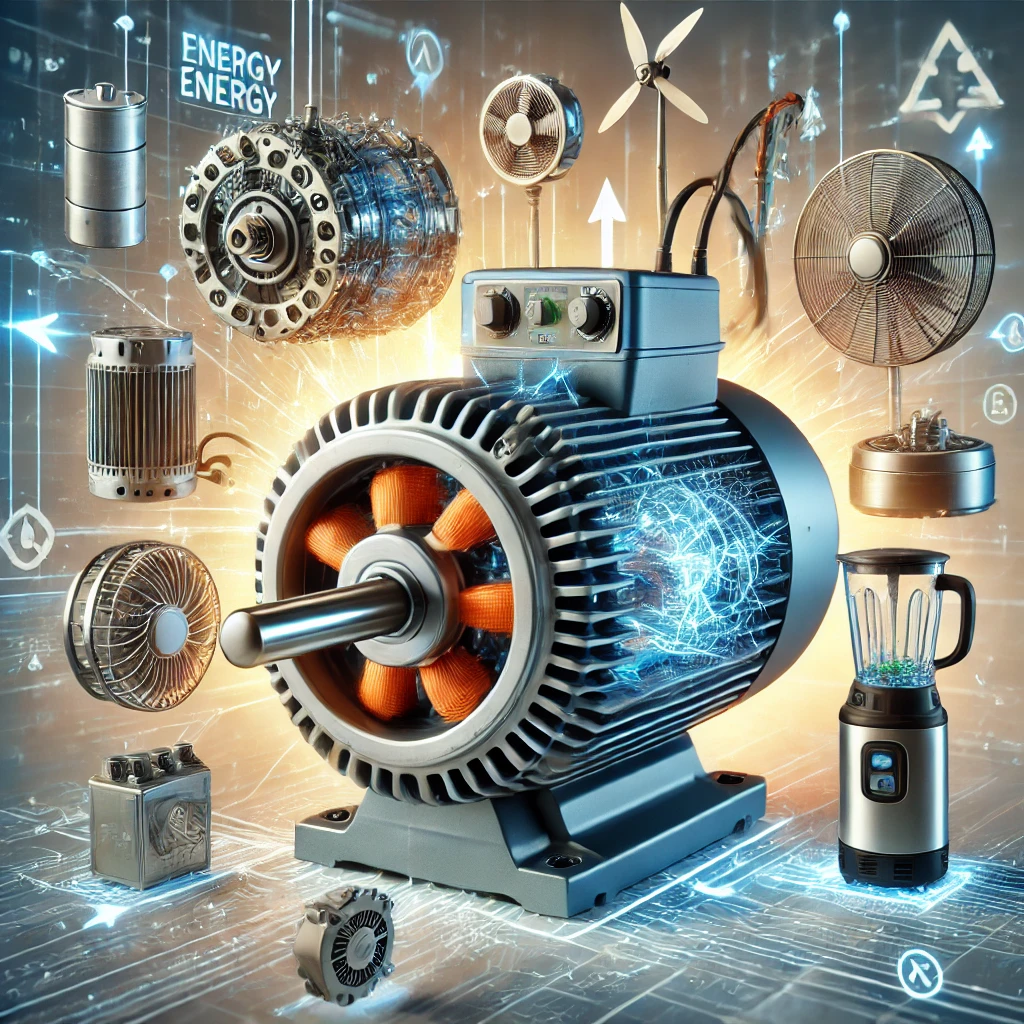

Electric motors have a rich history, dating back to the early 19th century with pioneers such as Michael Faraday and Nikola Tesla, who laid the foundation for modern electric technology. Faraday’s discovery of electromagnetic induction was a turning point, as it showed how electrical current could be used to create motion. Electric motors operate on this principle, where an electric current passes through windings (coils), generating a magnetic field that interacts with a rotor to create torque. This movement powers a wide range of devices, from small household appliances like blenders to large industrial machines. Tesla’s invention of alternating current (AC) further revolutionized electric motor design, making them more efficient and widely applicable across industries.

The Growing Role of Electric Motors in Sustainable Technology

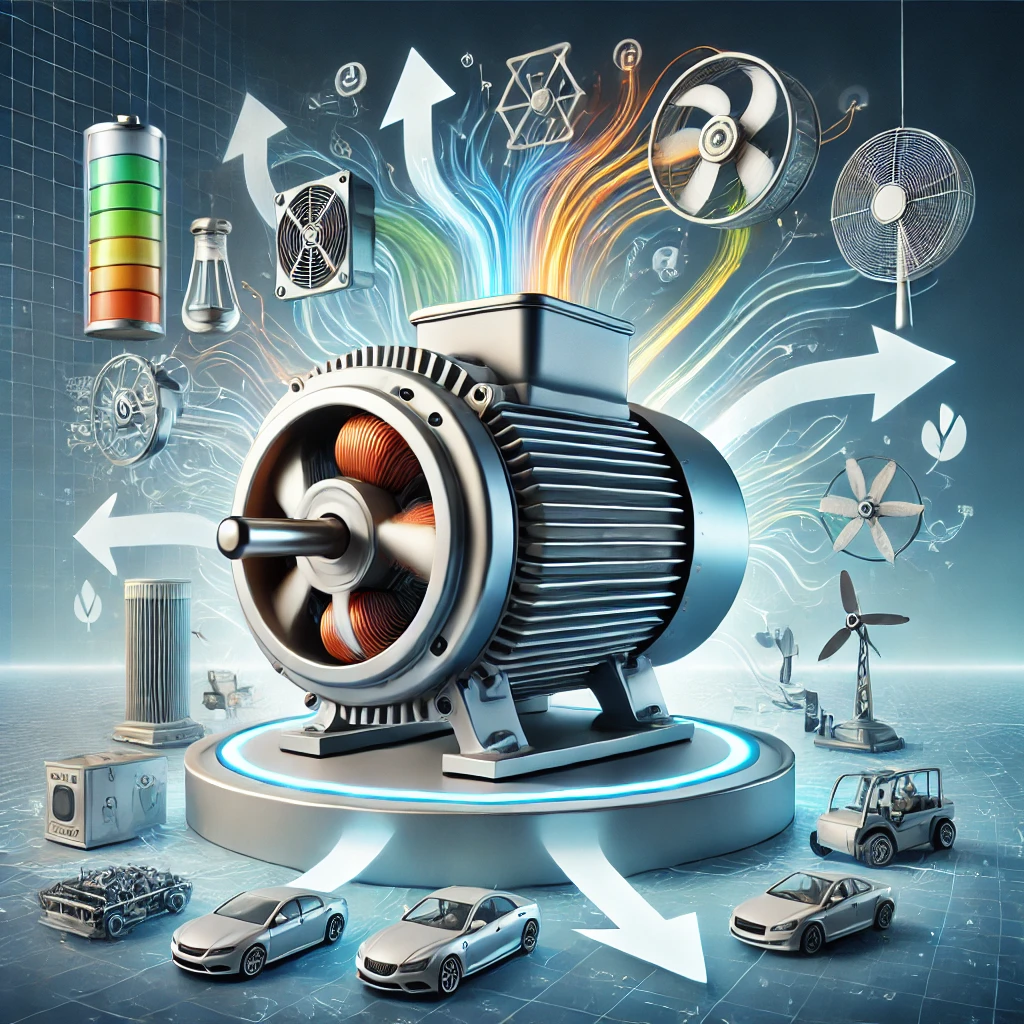

As society moves towards greener energy solutions, electric motors have become central to reducing environmental impact. Unlike internal combustion engines (ICE), which rely on fossil fuels and emit harmful gases, electric motors operate without direct emissions, making them crucial for sustainable energy use. Electric vehicles (EVs) exemplify this shift, as their motors efficiently convert stored electrical energy into motion, contributing to cleaner transportation. Additionally, electric motors power critical infrastructure in industries such as manufacturing and renewable energy generation, where wind turbines and solar power systems rely on motor-driven technologies. Their ability to run efficiently while producing fewer emissions makes electric motors indispensable for advancing eco-friendly technologies and achieving energy efficiency on a global scale.

How Electric Motors Use Electricity Based on Workload

Electric motors adjust their electricity consumption based on workload, making their energy usage dynamic. Under ideal conditions—consistent speeds and moderate loads—they run efficiently, using minimal power. However, when motors face increased demands, such as rapid acceleration in electric vehicles (EVs) or heavy lifting in industrial machinery, electricity consumption spikes. Conversely, under lighter loads or at lower speeds, they use less power. This variability is essential to understanding how to optimize energy efficiency, particularly in applications where reducing waste and maximizing output are priorities. By managing energy use based on the task at hand, electric motors can operate more efficiently across a wide range of applications.

Electricity Consumption and Efficiency Fluctuations in Motors

Electric motors, though efficient, consume varying amounts of electricity depending on conditions. In electric vehicles, for example, more power is needed when accelerating uphill or carrying heavy loads due to increased mechanical resistance. At lighter loads or steady speeds, energy use decreases, though efficiency can still vary by design. Motors with variable-speed control or advanced energy management systems help regulate these fluctuations, ensuring electricity consumption aligns with performance needs. This is essential for industries aiming to optimize energy use and minimize waste.

The Concept and Benefits of Regenerative Braking

Regenerative braking is a groundbreaking innovation in electric motor technology, especially in electric vehicles (EVs). Traditional braking systems dissipate energy as heat when slowing down a vehicle, leading to significant energy loss. Regenerative braking, on the other hand, captures kinetic energy during braking and converts it back into electrical energy, which is stored in the vehicle’s battery for later use. This process not only reduces energy waste but also improves overall efficiency by allowing the motor to reuse energy that would otherwise be lost. This feature is particularly advantageous for city driving, where frequent stops and starts occur, making regenerative braking a critical element in extending the range and reducing the energy consumption of EVs.

How Regenerative Braking Enhances Efficiency in Urban Driving

Regenerative braking is especially effective in urban environments where stop-and-go driving is common. By harnessing the energy generated during deceleration, this system allows electric vehicles to recover and store power instead of losing it to friction and heat, as is the case with conventional brake systems. For example, when an EV approaches a red light, regenerative braking captures the energy from the slowing wheels, helping to recharge the battery. This contributes to greater energy efficiency, prolongs battery life, and reduces reliance on external charging. In contrast to internal combustion engines, which are unable to recapture energy in this way, regenerative braking showcases one of the key advantages electric motors offer in terms of sustainable, efficient driving.

High-Speed Demands on Electric Motors

At high speeds, electric motors require more electricity due to increased air resistance and mechanical drag. As velocity rises, the motor must work harder to maintain performance, using continuous power from the battery. Unlike low-speed situations, where regenerative braking captures energy, high-speed operation demands a constant energy flow. This is common in electric vehicles (EVs) traveling on highways. However, even under these conditions, electric motors are more efficient than internal combustion engines, converting a greater percentage of energy into usable mechanical power. This makes them an attractive option for sustainable transportation, despite the increased energy consumption at higher speeds.

Technological Innovations for High-Speed Efficiency

Technological advances in motor design, battery capacity, and aerodynamics have improved electric motor efficiency at high speeds. Induction motors, found in some Tesla models, deliver high torque and efficiency at elevated velocities, reducing energy loss. Permanent magnet synchronous motors (PMSMs) also provide excellent performance across a range of speeds. Larger lithium-ion batteries, offering more capacity, extend range and optimize energy use in high-speed scenarios. Aerodynamic improvements in EV designs, such as the streamlined Tesla Model S, further reduce drag and energy consumption. These innovations help electric motors maintain efficiency at higher speeds, supporting their role in sustainable, long-distance travel.

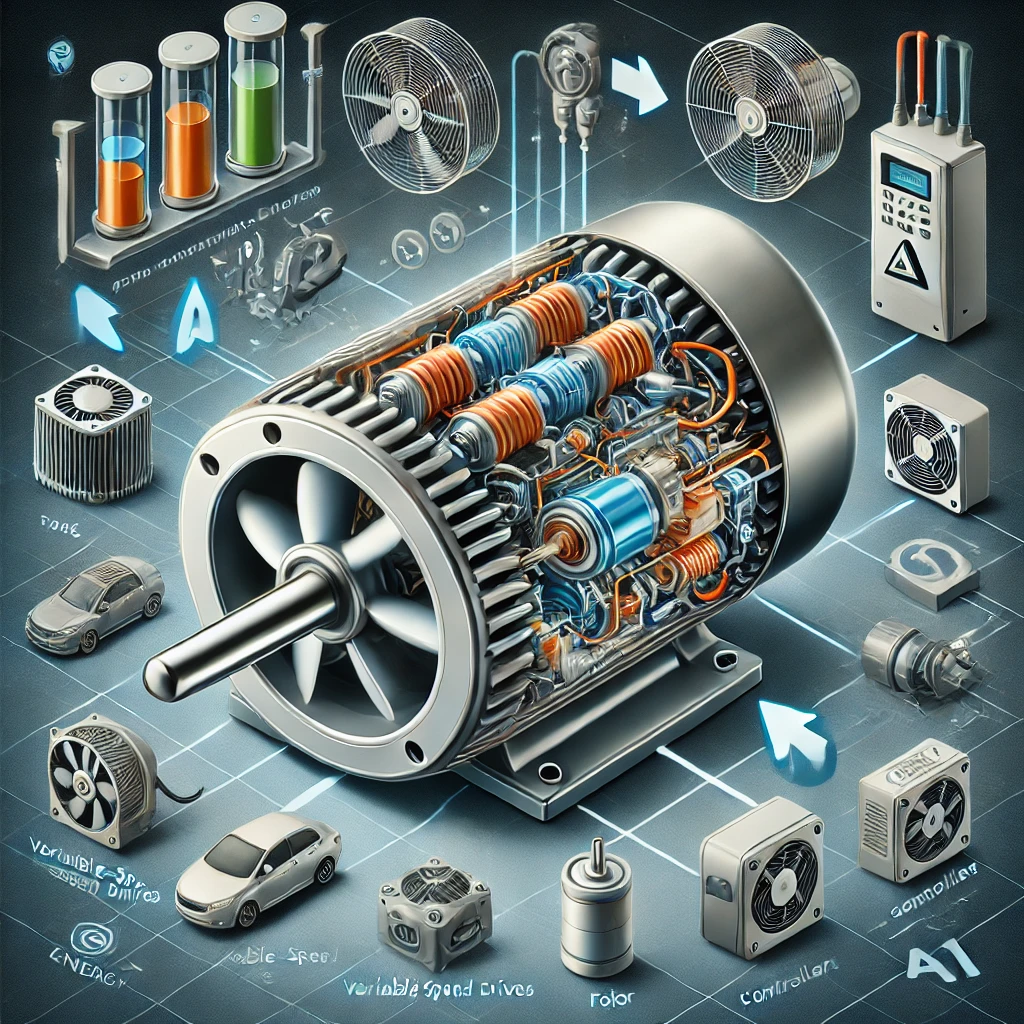

Variable Energy Output in Electric Motors

Modern electric motors are equipped with advanced controllers that regulate energy output based on real-time demands. Technologies like variable frequency drives (VFDs) help adjust the motor’s speed and torque, ensuring it only uses the electricity necessary for a given task. This system is similar to how internal combustion engines control fuel intake to match power output. For example, when an electric vehicle (EV) needs more power during acceleration or less during cruising, the motor controller adjusts accordingly. By optimizing power use, electric motors become more efficient and reduce energy waste, making them ideal for applications requiring flexible energy management.

The Role of Motor Controllers in Efficiency

Motor controllers are crucial for enhancing the efficiency of electric motors, especially in electric vehicles. These controllers manage energy flow, allowing for smooth acceleration and controlled deceleration. This precision improves not only energy efficiency but also overall performance. For instance, in an EV, the controller reduces unnecessary power usage by adjusting energy output to meet specific driving conditions. This ability to match power needs in real-time makes electric motors more adaptable, significantly cutting down on energy wastage. The technology ensures that electric motors are highly efficient and suitable for applications requiring precise energy control, from EVs to industrial machinery.

Real-Time Energy Regulation in Electric Motors

Electric motors regulate energy output through controllers that modulate electricity use based on demand. Unlike gas engines, which adjust fuel intake, electric motor controllers optimize performance across different speeds and workloads. This system helps motors operate more efficiently, but they still face challenges in achieving the same level of real-time flexibility as internal combustion engines. Factors like battery technology limit how quickly electric motors can respond to changes in power needs. Although motor controllers have made electric motors more adaptable, there are still areas for improvement in real-time energy regulation.

Advances in Battery and Energy Management Technology

Battery technology plays a key role in improving the real-time energy regulation of electric motors. Modern innovations in energy storage and management systems are narrowing the gap between electric and gas engines in terms of responsiveness. For example, better battery designs and more efficient energy management systems are helping electric motors adjust to varying power demands more quickly. These advances make electric motors more flexible and capable of meeting performance needs across different conditions. However, achieving perfect real-time energy efficiency remains a challenge, with ongoing research focused on further optimizing battery performance and energy management.

Permanent Magnet Synchronous Motors (PMSMs)

Permanent Magnet Synchronous Motors (PMSMs) are among the most efficient electric motors, commonly used in electric vehicles (EVs) due to their high performance and energy efficiency. PMSMs maintain consistent power across a range of speeds, allowing vehicles to operate optimally without significant energy loss. These motors rely on permanent magnets to generate a magnetic field, reducing the need for additional electrical power. This makes them ideal for applications that require high efficiency and reliability. PMSMs are particularly valued in EVs like the Tesla Model 3, where they provide strong torque and smooth acceleration while minimizing energy waste, contributing to both performance and environmental sustainability.

Induction Motors in Industrial Settings

Induction motors are widely used in industrial applications due to their ability to adjust power output based on workload. These motors are highly efficient and durable, making them suitable for environments where variable speed and torque control are needed. Induction motors work through electromagnetic induction, where electrical current induces a magnetic field that powers the rotor. This adaptability makes them perfect for industries such as manufacturing and heavy machinery, where energy efficiency and performance are critical. By minimizing wasted electricity, induction motors help reduce operational costs and support energy-saving initiatives, making them a cornerstone of sustainable industrial practices.

Energy Wastage in Common Household Electric Motors

Household appliances like box fans, blenders, and mixers rely on electric motors with multiple speed settings, but they often waste energy due to inefficient design. In many older models, the motor uses nearly the same amount of electricity regardless of speed. A mechanical dampener slows the motor output without reducing the energy input, meaning the motor continues to consume full power even at lower speeds. This leads to unnecessary electricity usage, increasing both energy costs and environmental impact. These inefficiencies highlight the need for more advanced energy-saving technologies in everyday appliances.

Improving Efficiency with Variable-Speed Drives

Recent advancements in appliance design are addressing these inefficiencies by incorporating variable-speed drives in household electric motors. Unlike traditional models, these drives adjust the motor’s power based on the speed setting, ensuring that the motor draws only the necessary amount of electricity for the task. This technology significantly reduces energy wastage, making appliances like fans and mixers more efficient. For example, a fan equipped with a variable-speed drive uses less electricity on lower settings, directly lowering power consumption. These innovations are improving household energy efficiency, helping consumers save on energy bills and reduce their environmental footprint.

Energy Management: Gas Engines vs. Electric Motors

Gas engines regulate energy output by adjusting fuel flow, offering flexible management in response to varying demands. This real-time adaptability allows internal combustion engines to quickly change power levels based on driving conditions. In contrast, electric motors, while more efficient overall, face limitations in real-time energy input adjustment. Though technologies like variable frequency drives (VFDs) help control the relationship between energy input and output, electric motors still lag behind gas engines in dynamic responsiveness, especially under sudden load changes. This difference is most evident in situations requiring rapid power adjustments, such as sudden acceleration or steep inclines.

Closing the Gap with Electric Motor Efficiency

Despite their limitations in real-time energy regulation, electric motors consistently outperform gas engines in overall efficiency. Electric motors convert a higher percentage of energy into usable power, particularly under optimal load conditions. As battery technology advances and real-time regulation systems improve, the gap between gas engines and electric motors will continue to narrow. Innovations in energy storage, such as higher-capacity batteries and smarter energy management systems, are making electric motors more responsive to changes in power needs. These developments promise better performance and efficiency, positioning electric motors as a superior alternative to traditional internal combustion engines for many applications.

Challenges in Optimizing Electric Motor Efficiency

While electric motors are known for their high efficiency, optimizing energy use under varying loads remains challenging. Factors such as heat generation and mechanical resistance cause energy losses, reducing overall efficiency. Even with innovations like regenerative braking and advanced motor controllers, these issues persist. Electric motors can struggle to maintain optimal performance when faced with fluctuating workloads, which is common in industrial applications and electric vehicles (EVs). As a result, improving energy efficiency across diverse operating conditions continues to be a focus for engineers and researchers.

Advancements Needed for Enhanced Efficiency

Overcoming these efficiency challenges requires further advancements in key areas, such as battery technology, cooling systems, and energy storage. Efficient heat management is critical, as excess heat can cause significant energy losses in motor-driven systems. Moreover, enhancing battery capacity and energy storage technology will allow electric motors to perform better under varying loads. These improvements are particularly important for industrial applications that demand precise power control and for EVs, where optimal energy management is crucial to extending range and performance. Continuous innovation in these areas will be essential to ensuring electric motors achieve maximum efficiency across all conditions.

AI and Smart Motor Controllers for Improved Energy Regulation

New technologies in electric motor design are addressing the need for enhanced energy regulation. Artificial intelligence (AI) is increasingly being integrated into motor controllers, allowing these systems to predict and adapt to changing loads and operating conditions. By dynamically adjusting power output, AI-enabled controllers optimize electricity consumption, reducing energy waste and improving efficiency. For example, in electric vehicles (EVs), AI can help motors deliver the right amount of power for acceleration or cruising, making the system more responsive to real-world demands. These advancements make electric motors more adaptable and efficient, bringing them closer to the energy management capabilities of internal combustion engines.

Emerging Materials for Greater Efficiency

In addition to AI, new materials like superconductors are being explored to improve electric motor efficiency. Superconductors eliminate electrical resistance, reducing energy loss and enhancing overall performance. Though still in the early stages of development, these materials have the potential to revolutionize how electric motors operate by allowing them to regulate power output more efficiently. The combination of AI-driven motor controllers and advanced materials like superconductors could enable electric motors to adjust their energy consumption in real-time, similar to gas engines but with far less environmental impact. These innovations hold great promise for the future of energy-efficient motor technology.

The Future of Electric Motor Innovation

Electric motors are poised for continued advancements in efficiency, design, and performance, particularly as battery technology evolves. Emerging technologies such as solid-state batteries, which offer higher energy density and faster charging times, will make electric motors even more efficient and reliable. AI-driven motor management systems will further optimize electricity use by responding dynamically to real-world conditions, such as changing terrain or workload. As these innovations mature, electric motors will continue to challenge the dominance of internal combustion engines, offering cleaner, more energy-efficient solutions for transportation, manufacturing, and everyday household applications.

Summary of Electric Motor Efficiency and Innovations

Electric motors convert electrical energy into mechanical motion, with energy consumption varying based on load and performance needs. Innovations such as regenerative braking improve efficiency at low speeds, while motor controllers regulate power output at higher speeds. Although many household appliances still waste energy due to outdated designs, newer models with variable-speed drives are addressing this issue. The integration of AI-driven controllers and advances in battery technology are enhancing real-time energy regulation, allowing electric motors to rival or even surpass gas engines in efficiency. As these technologies continue to evolve, electric motors will become increasingly vital in promoting sustainable energy use across industries and everyday applications.

How useful was this post?

Click on a star to rate it!

Average rating / 5. Vote count:

No votes so far! Be the first to rate this post.

Author

-

Meet Dr. Kendall Gregory, a highly accomplished professional with a remarkable academic background and a deep passion for empowering individuals through knowledge. Dr. Gregory’s educational journey began with a Bachelor of Science degree, followed by a Doctor of Chiropractic Medicine, focusing on diagnosing and treating musculoskeletal conditions. He further expanded his expertise with a Master's degree in Oriental Medicine, specializing in acupuncture and Chinese herbology, and a Master's degree in Health Care Administration, emphasizing his dedication to improving healthcare systems. Dr. Gregory combines his extensive knowledge and practical experience to provide comprehensive and integrative healthcare solutions. Through his writings, he aims to inspire individuals to take charge of their health and make informed decisions.

View all posts

[…] astronomy continues to unravel the mysteries of the Orion Arm using advanced technology and observational techniques. Space missions like the Gaia spacecraft have provided precise […]

[…] and endless adventures provided a depth of gameplay that was unprecedented. The combination of technological achievement and innovative game design made Norrath a living, breathing world. The sense of […]

[…] die-hard enthusiasts, keeping the franchise relevant across generations. By blending cutting-edge technology with the series’ trademark storytelling, Dragon Ball’s gaming ventures continue to captivate […]